We just completed a fine tool box course. Each student built a very handsome box, complete with 4 drawers that were veneered in black walnut, which we resawed. I chose a superior grade of alder for each box, which was absolutely lovely to work with. Traditionally tool boxes were built using pine because it is lightweight. It is somewhat hard to find very clear pine down here, and the alder is quite light weight so I thought it would be good choice. If you have never worked with it, you really should try it out. It is amazingly easy to handplane and is very predictable. It also finishes to a beautiful brown color with a hint of red. I have heard it referred to as poor man’s cherry or western cherry. I found it much easier to work than cherry and the price is better too!

Here is Rogers cutting a tapered sliding dovetail for the drawers to ride on.

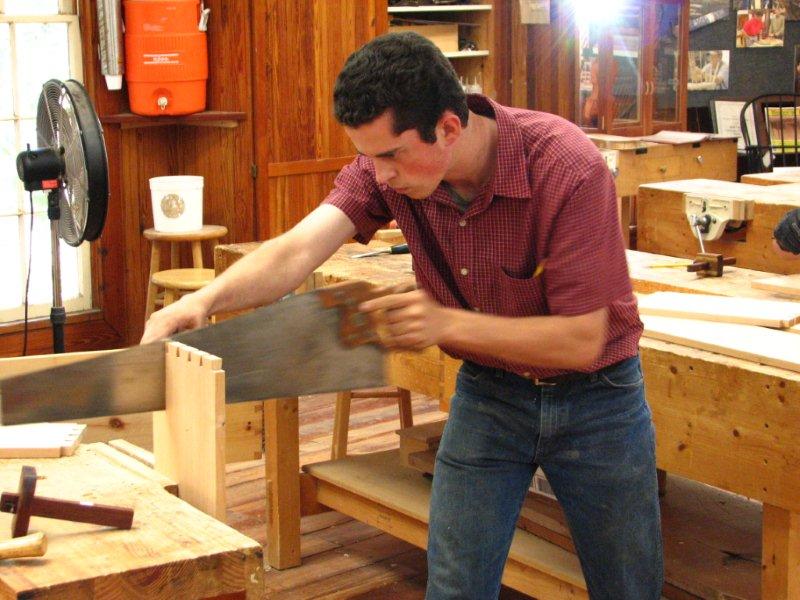

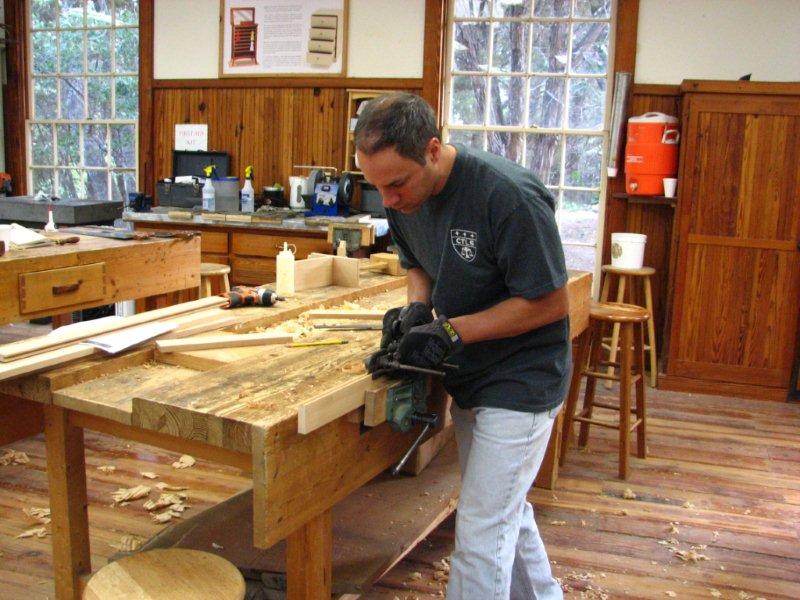

Here are a few more pictures, one of Steve chiseling out the waste on his dovetail and Tim sawing the box side down.

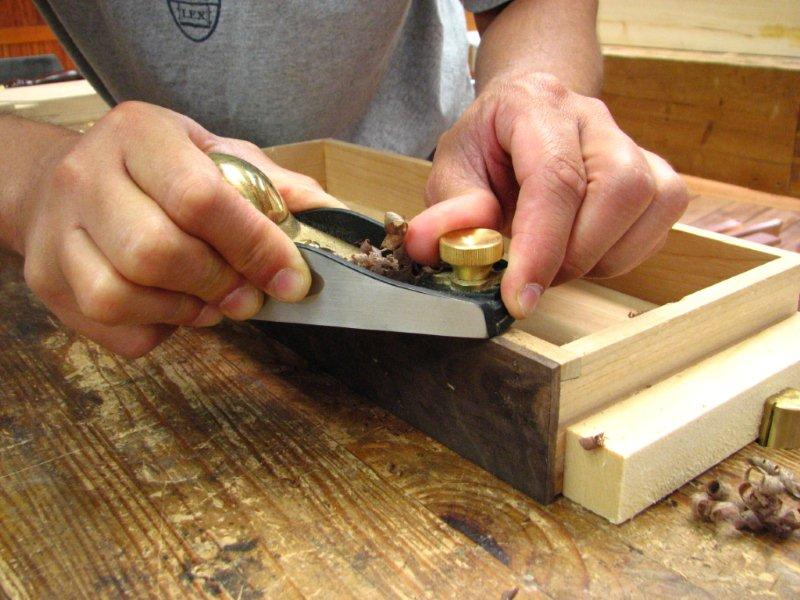

Steve is using a plow plane to plane the grooves for the back panel. This plane is an old Stanley #50 with a patent date of 1883. It works as good as new!

We glued the walnut veneer using hide glue, then cleaned it up with planes and scrapers.

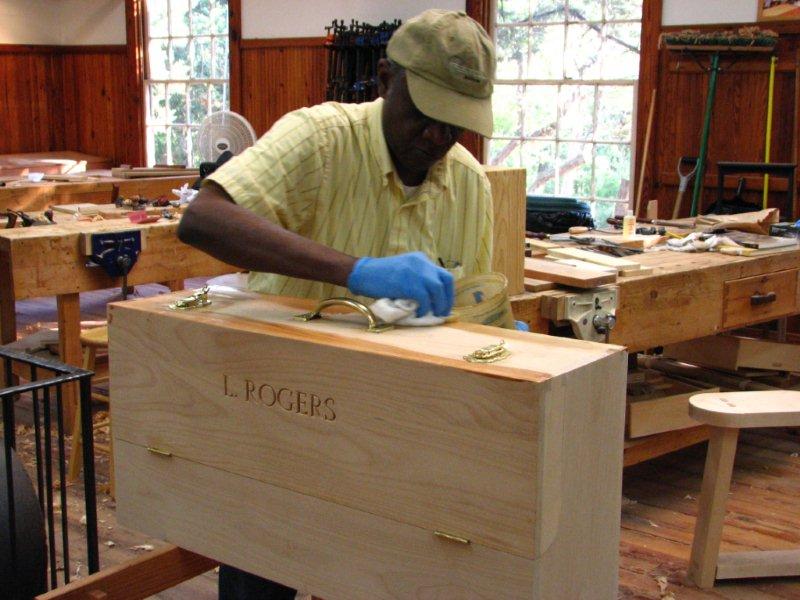

Here is Rogers oiling his tool box with Deft Danish Oil. And then his finished box.

Here we are with the finished boxes. This class covers many aspects of hand tool woodworking, from making a frame and panel with mortise and tenons for the back, to dovetailing the whole box, as well as the drawers. We will have another class scheduled for next year and will post the dates within a couple of months.

Comments are closed.