Marking out dovetails

Now that the layout for the dovetails has been done, it’s time to start cutting!

I am using a Moxon vise to hold the boards in place for two reasons, one it gets it up to a more comfortable cutting height and two, it supports it nicely across the entire width.

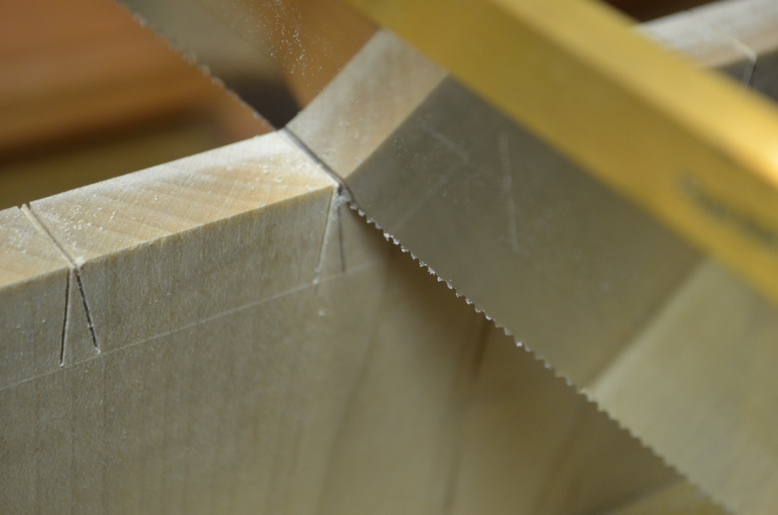

I start by sawing with my new fine Lie-Nielsen dovetail saw, it is best to cut all the same angles one way and then come back and cut the other angles the other way. I am making needle point dovetails here as you can see from the pictures, leaving just a fuzz between the tails offers a bit of a challenge.

Cutting needle point dovetials

I prefer to cut out the waste with a coping saw, just above the line and then trim right to the line using a chisel. (If you’re looking for some coping saw blade suggestions, try out this post.)

Coping out the waste

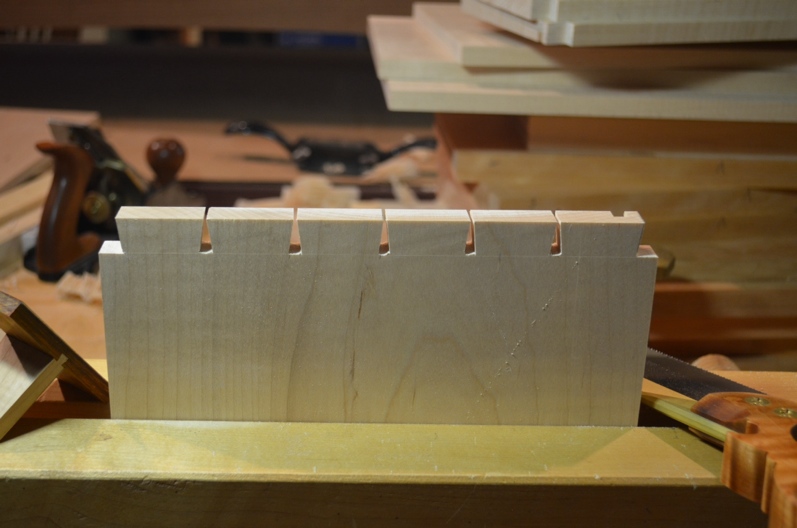

A finished set of tails

I layout each set of tails and then cut them, working sequentially. I cut all the tails before starting on the pins.

The transfer of the tails to the pins must be done with the utmost accuracy. I am using a knife–it really is the only way to get inside the small space of the tail.

Knife marking the tails to the pins

Cutting the half blind pins must be done by sawing at an angle. This poses a little bit of a challenge as you are trying to cut both the angle of the tail, plus cut straight down plus at an angle so that you don’t cut into the drawer front. Sound confusing? Well, if you do several hundred of these you will find that it does get a little easier!

Cutting the half blind pins

Chiseling out the waste in between the pins is the only way, you can’t using the coping saw because it is half blind.

Chiseling out the half blind pins (my helper is in the back!)

The back of the drawers are also dovetailed, using a full through dovetail. I extended the tails long so that they will hit the back stop before the entire back hits the backstop. This makes it easier when you are trying to fit the drawer stop and it allows you to be able to adjust the back of the drawer as needed.

Now that I have over 120 dovetails cut it is time to turn my attention to gluing up the drawers. I have been cutting dovetails since I was 11 years old, so I usually don’t test fit the dovetails. I know they are going to fit–or at least I hope they are going to fit! However, sometimes I will test them part way, just to make sure they are going to knock together all the way home.

In the next post I will tell you a little about the process of gluing and what kind of glue that I like to use for the dovetails.

Frank Strazza

P.S. I am a little behind on my blogging of the dresser progress, I actually delivered the finished dresser just the other day, to a show where it will be on display for a month. More on that in upcoming posts so stay tuned!

Read all about Frank’s dresser project progress.

To see Frank’s dovetail making in action, sign up for our online Basics of Joinery Course to watch our online video, Cutting the Dovetail Joint, and get other in-depth classes on dovetails and other joints. To preview the Joinery course, see our free video, A Dovetail Demonstration. For a full-blown dresser project, sign up for our on campus Four Drawer Dresser course.

Comments are closed.