Well we survived another Craftsman Rocking Chair class! Now there are five more people who understand why quality furniture costs so much! We pushed hard the whole class so we wouldn’t have to leave at midnight on Saturday.

I’ve been realizing how much the majority of people have absolutely no idea how much work it takes to build a handmade quality piece of furniture. It’s a good thing this kind of furniture can pass from generation to generation! (It’s not something your going to find at the local furniture factory). Not only can you keep the rocking chair in the family for generations, but you made it yourself with your own hands! I find that very rewarding.

Also you will probably be happy to hear we just installed a piece of non-glare glass to go in front of the video screen. It’s going to help a lot when you can actually see what the camera is focused on instead of the reflection of the front door every time a visitor walks in!

Monday we made the front frame; mortises, (some were done on the machine… sorry Frank) tenons, the tenon that passes through the arm, cut the arch, planed, scraped and sanded all the parts, then glued up.

Tuesday we started on the back frame, doing mortises, tenons and fitting.

Wednesday was spent cutting the mortises that house the back slats and fitting them in place, final fitting of the tenons, and finally glued it up.

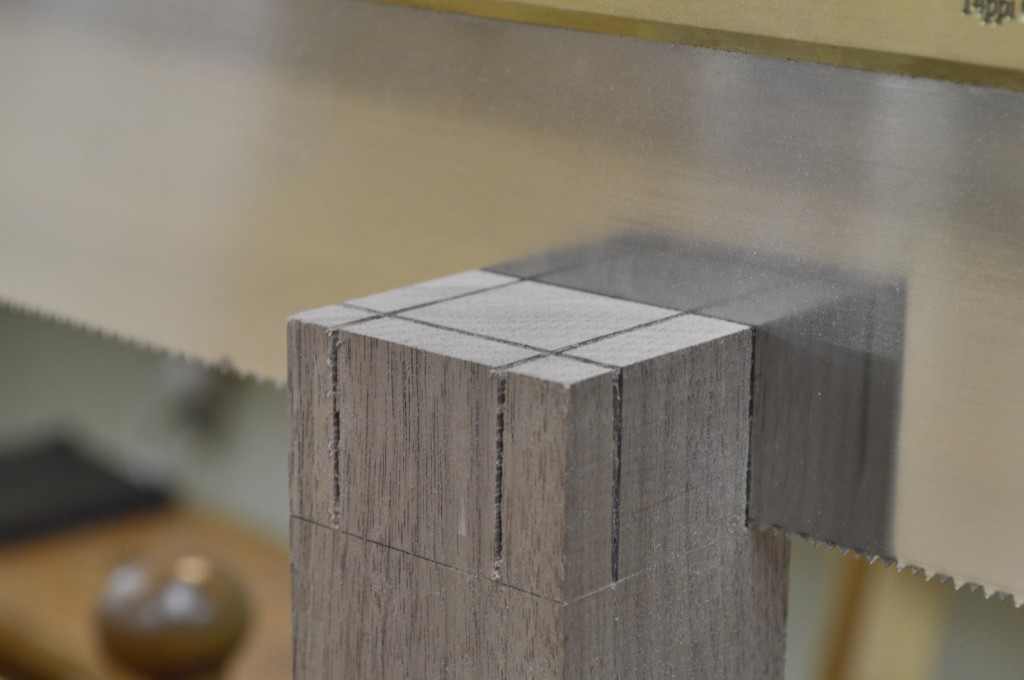

Thursday was angled tenons! If you want to get confused come learn about them! We cut and fit each angled tenon, checking and double checking to make sure they had been laid out correctly before cutting.

Friday we glued up the side rails connecting the back frame with the front frame, and started the arms.

Saturday we finished the arms, cut the legs to length and made the tenons that fit into the rockers. Then cut the mortises into the rockers and fit them.

A happy chair owner!

Enjoy your chairs,

Jonathan Schwennesen

Comments are closed.